A204 Pressure Vessel Steel Plate

Classification :

PRODUCT DETAILS

A204 Pressure Vessel Steel Plate Description

ASTM A204 boiler vessel plate is molybdenum alloy steel plate, mainly suitable for welding boilers and high temperature pressure vessels. According to the molybdenum content, ASTM A204 boiler container plate is divided into 3 grades: A, B, C. The thickness of ASTM A204 boiler vessel plates is limited only by the ability of the chemical composition to meet the specified mechanical property requirements.

Product Parameters

|

Product Name |

A204 Pressure Vessel Steel Plate |

|

Production Process |

Hot Rolling, Cold Rolling |

|

Material Standards |

AISI, ASTM, ASME, DIN, BS, EN, ISO, JIS, GOST, SAE, etc. |

|

Width |

100mm-3000mm |

|

Length |

1m-12m, or Customized Size |

|

Thickness |

0.1mm-400mm |

|

Delivery Conditions |

Rolling, Annealing, Quenching, Tempered or Standard |

|

Surface Process |

Ordinary, Wire Drawing, Laminated Film |

Chemical Composition

|

A204 |

Upper limit of Chemical Element Content (%) |

|||||

|

C |

Si |

Mn |

P |

S |

Mo |

|

|

Class A |

0.18-0.25 |

0.13-0.45 |

0.90-0.98 |

0.035 |

0.035 |

0.45-0.60 |

|

Class B |

0.20-0.27 |

0.13-0.45 |

0.90-0.98 |

0.035 |

0.035 |

0.45-0.60 |

|

Class C |

0.23-0.28 |

0.13-0.45 |

0.90-0.98 |

0.035 |

0.035 |

0.45-0.60 |

Mechanical Properties

|

A204 |

Tensile Strength kis[MPa] |

Yield Strength kis[MPa] |

Elongation Gauge length 8in.[200mm],% |

Elongation Gauge length 2in.[50mm],% |

|

GradeA |

70-90 [485-620] |

37 [255] |

19 |

23 |

|

GradeB |

75-95 [515-655] |

40 [275] |

17 |

21 |

|

GradeC |

75-95 [515-655] |

43 [295] |

16 |

20 |

Physical Performance

|

Physical Performance |

Metric |

Imperial |

|

Density |

7.80g/cc |

0.282 lb/in³ |

Scope of Application

ASTM A204 boiler vessel plate is widely used in petroleum, chemical industry, power station, boiler and other industries, used in the manufacture of reactors, heat exchangers, separators, spherical tanks, liquefied gas, nuclear reactor pressure vessels, boiler drum steam, liquefied petroleum gas, hydropower stations, high pressure pipelines, etc.

| China | USA | Germany | Japan | France | U.K. | internationality |

|

GB3077 |

AlSI |

DIN |

JIS |

NE |

BS |

ISO |

|

20Mn2 |

1320 1221 |

20Mn5 |

SMn21 |

20M5 |

150M19 |

- |

|

30Mn2 |

1330 |

30Mn5 |

SMn24 |

32M5 |

150M28 |

- |

|

35Mn2 |

1335 |

36Mn5 |

SMnl |

35M5 |

150M36 |

- |

|

40Mn2 |

1340 1341 |

- |

SMn2 |

40M5 |

- |

- |

|

45Mn2 |

1345 |

46Mn7 |

SMn3 |

45M5 |

- |

- |

|

50Mn2 |

1052 |

50Mn7 |

- |

55M5 |

- |

- |

|

20MnV |

- |

20MnV6 |

- |

|

- |

- |

|

30Mn2MoW |

- |

-- |

- |

|

- |

- |

|

27SiMn |

- |

27MnSi5 |

- |

|

- |

- |

|

35SiMn |

- |

37MnSi5 |

- |

38MS5 |

- |

- |

|

42SiMn |

- |

38MnSi4 46MnSi4 |

- |

38MS5 |

- |

- |

|

20SiMn2MoV |

- |

- |

- |

- |

- |

- |

|

25SiMn2MoV |

- |

- |

- |

- |

- |

- |

|

37SiMn2MoV |

- |

- |

- |

- |

- |

- |

|

40B |

14B35 |

35B2 |

- |

- |

- |

- |

|

45B |

50B46H |

45B2 |

- |

- |

- |

- |

|

50B |

14B50 |

- |

- |

- |

- |

- |

|

4OM∏B |

15B41 |

- |

- |

- |

- |

- |

|

45MnB |

15B48 50B44 |

- |

- |

- |

- |

- |

|

20Mn2B |

- |

- |

- |

- |

- |

- |

|

20MnMoB |

80B20 |

- |

- |

- |

- |

- |

|

15MnVB |

- |

- |

- |

- |

- |

- |

|

- |

- |

- |

- |

- |

- |

- |

|

- |

- |

- |

- |

- |

- |

- |

|

20MnVB |

- |

- |

- |

- |

- |

- |

|

40MnVB |

- |

- |

- |

- |

- |

- |

|

20MnTiB |

- |

- |

- |

- |

- |

- |

|

25MnTiBRE |

- |

- |

- |

- |

- |

- |

|

2OSiMnVB |

- |

- |

- |

- |

- |

- |

|

15Cr |

5015 5115 |

15Cr3 |

SCr21 |

12C3 |

523A14 523M15 |

- |

|

15CrA |

- |

- |

- |

- |

- |

- |

|

20Cr |

5120 |

20Cr4 |

SCr22 |

18C3 18C4 |

527A19 527M20 |

683/11 20Cr4 20CrS4 |

|

30Cr |

5130 |

28Cr4 |

SCr2 |

28C4 32C4 |

530A30 530A32 |

- |

|

35Cr |

5135 |

34Cr4 37Cr4 |

SCr3 |

38C4 |

530A36 |

683/8 3、 3a、 3b |

|

40Cr |

5140 |

38Cr4 41Cr4 |

SCr4 |

42C4 |

530A40 530M40 |

683/1 4、 4a^ 4b |

|

45Cr |

5145 |

42Cr4 |

SCR5 |

45C4 |

- |

- |

|

50Cr |

5150 5152 |

- |

- |

50C4 |

En48 |

- |

|

38CrSi |

- |

- |

- |

- |

- |

- |

|

12CrMo |

4119 |

13CrMo44 |

- |

12CD4 15CD2 |

- |

- |

|

15CrMo |

ASTM A-387Gr. B |

15CrMo5 16CrMo44 |

SCM21 |

15CD4. 05 |

BS1653 |

- |

|

20CrMo |

4118 |

20CrMo5 22CrMo4 |

SCM22 |

18CD4 20CD4 |

CDS 12 CDSllO |

- |

|

30CrMo |

4130 |

25CrMo4 |

SCM2 |

30CD4 |

CDS 13 |

- |

|

30CrMoA |

- |

32CrMol2 3ICRMo12 |

- |

- |

- |

- |

|

35CrMo |

4135 4137 |

34CrMo4 35CrMo4 |

SCM3 |

35CD4 |

78A37 |

683/1 C35ea C35eb |

|

42CrMo |

4140 4142 |

41CrMo4 42CrMo4 |

SCM4 |

40CD4 42CD4 |

708M40 708A42 709M40 |

683/1 3 |

|

12CrMoV |

- |

- |

- |

- |

- |

- |

|

35CrMoV |

- |

35CrMoV5 |

- |

- |

- |

- |

|

12CrlMoV |

- |

13CrMoV4.2 |

- |

- |

- |

- |

|

25Cr2MoVA |

- |

24CrMoV5.5 |

- |

- |

- |

- |

|

25Cr2MolVA |

- |

- |

- |

- |

- |

- |

|

20CR3MoWVA |

- |

21CrVMoW12 |

- |

- |

- |

- |

|

38CrMoΛl |

6370 (ΛMS) |

34CrAlMo5 41CrAlMo7 |

SACM645 |

40CAD6.12 |

905M39 |

683/10 41CrAlMo74 |

|

20CrV |

6120 |

22CrV4 |

- |

22CrV4 |

- |

- |

|

40CrV |

6140 |

42CrV |

- |

42CrV4 |

- |

- |

|

50CrVA |

6150 |

50CrV4 |

SUPlO |

50CV4 |

735A50 |

- |

|

15CrMn |

- |

16MnCr5 |

- |

16MC5 |

- |

- |

|

20CrMn |

5120 |

20MnCr5 |

SMC21 |

20MC5 |

- |

- |

|

40CrMn |

5140 |

- |

SMC3 |

- |

- |

- |

|

20CrMnSi |

- |

- |

|

- |

- |

- |

|

25CrMnSi |

- |

- |

SMKl |

- |

- |

- |

|

30CrMnSi |

- |

- |

- |

- |

- |

- |

|

30CrMnSiA |

- |

- |

- |

- |

- |

- |

|

35CrMnSiA |

- |

- |

SMK2 |

- |

- |

- |

|

20CrMnMo |

4119 |

20CrMo5 |

SCM23 |

- |

- |

- |

|

40CrMnMo |

4140 |

- |

- |

- |

- |

- |

|

20CrMnTi |

- |

- |

SMK22 |

- |

- |

- |

|

30CrMnTi |

- |

30MnCrTi4 |

- |

- |

- |

- |

|

20CrNi |

3120 |

20NiCr6 |

- |

20NC6 |

637A16 637M17 |

- |

|

40CrNi |

3140 |

46NiCr6 |

SNCl |

35NC6 |

640A35 640M40 |

- |

|

45CrNi |

3145 |

45NiCr6 |

- |

- |

- |

- |

|

50CrNi |

3150 |

- |

- |

- |

- |

- |

|

12CrNi2 |

3115 |

14NiCrlO |

SNC21 |

IONCll 14NC11 |

- |

- |

|

12CrNi3 |

3310 |

13NiCrl2 |

SNC22 |

10NC12 14NC12 |

655A12 655M13 |

- |

|

20CrNi3 |

- |

22NiCrl4 |

- |

20NC11 |

- |

- |

|

30CrNi3 |

- |

28NiCrlO 31NiCrl4 |

SNC2 |

30NC11 30NC12 |

- |

- |

|

37CrNi3 |

- |

35NiCrl8 |

SNC3 |

35NC15 |

- |

- |

|

12Cr2Ni4 |

E3310 |

14NiCrl8 |

- |

12NC15 |

- |

- |

|

20Cr2Ni4 |

E3316 |

22NiCrl4 |

- |

20NC14 |

659A15 659M15 |

- |

|

20CrNiMo |

8620 8720 |

20NiCrMo2 21NiCrMo2 |

- |

20NCD2 |

805A20 805M20 |

- |

|

40CrNiMoA |

4340 9840 |

36NiCrMo4 40NiCrMo6 |

SNCM8 |

35NCD5 40NCD3 |

817M40 816M40 |

- |

|

45CrNiMoVA |

4437 |

- |

SNCM9 |

- |

- |

- |

|

18Cr2Ni4WA |

|

|

|

|

|

|

|

25Cr2Ni4WA |

|

|

|

|

|

|

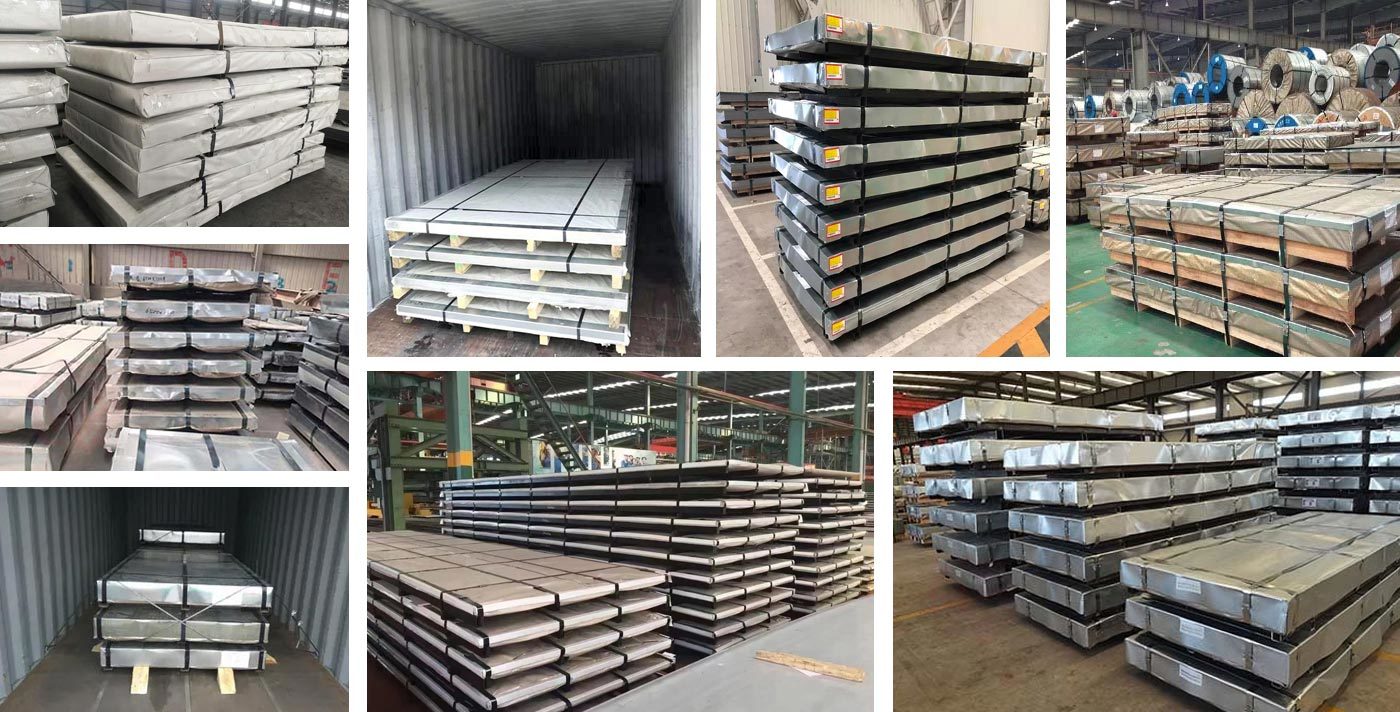

Packing and delivery

The company is equipped with a complete product production line. The main devices include cutting machines, bending machines, punching machines, cutting machines, polishing machines, shear machines, wire drawing machines, etc. Our traditional advantages are sufficient inventory, excellent quality, low -cost, short -term delivery time and considerate services.

CLIENT FEEDBACK

He company's products sell well all over the world, and have been exported to more than 70 countries in the Middle East, South Africa, Southeast Asia, Latin America and other regions Since its establishment, the company has developed rapidly.

CUSTOMER VISIT

Our company 'management has been engaged in steel industry for more than 20 years, full of experience for managing team and strong business relations with our valuable customers and factories.

Customer Visit

Customer Visit

Customer Visit

APPLICATION AREAS

Ship

Wind power

Oil mining

Airplane

Motorcycle

Car manufacturing

Mining

FACTORY WORKSHOP

FAQ

Q: Are you a manufacturer?

Q: How can we get the offer?

Q. Are your prices competitive?

Q: Can we visit your factory?

Q: How can we get the offer?

Q: Do you provide samples? is it free or extra?

RELATED PRODUCTS

GET A FREE QUOTE