Galvanized Unequal Angle Steel

Classification :

PRODUCT DETAILS

Product Description

Galvanized angle steel is divided into hot-dip galvanized angle steel and cold galvanized angle steel. Hot dip galvanized angle steel is also called hot dip galvanized angle steel or hot dip galvanized angle steel. The cold galvanized coating mainly ensures the full contact between zinc powder and steel through electrochemical principle, and generates electrode potential difference for anti-corrosion. Hot dip galvanized angle steel is also called hot dip galvanized angle steel or hot dip galvanized angle steel. It is to immerse the angle steel after derusting in molten zinc melted at about 500 ℃ to attach a zinc layer to the surface of the angle steel, thus achieving the purpose of anti-corrosion. It is suitable for strong corrosive environments such as various strong acids and alkali fogs. The cold galvanizing process is used to protect the metal from corrosion. For this purpose, a coating of zinc filler is used. It is applied to the protected surface by any coating method and dried to form a zinc filler coating with a content of zinc in the dried coating (up to 95%). Suitable for repair work (I. e., during repair work, only where the protected steel surface is damaged, the surface can be recoated as long as it is repaired). The cold galvanizing process is used for corrosion protection of various steel products and structures.

Product Parameters

|

Material |

A36,St37,S235J0,S235J2,St52,16mn,S355JOQ195,Q215,Q235B,Q345B,S235JR,S355JR,S355,SS440,SM400A,SM400BA572,GR50,GR60,SS540 |

|

Scope of production |

H100*100-H400*400H150*75 -H900*300 |

|

Thickness |

1-30mm |

|

Width |

15-400mm |

|

Length |

6m, 9m, 12mor according to customer requirements |

|

Technology |

Hot rolled, welded |

|

Standard |

ASTM,AISI,JIS,GB, DIN,EN |

|

Surface |

Galvanized, painted;or according to your requirements |

|

supply capacity |

2000tons/Day |

|

Business Type |

Manufacturer |

|

Certificate |

ISO, SGS,BV |

|

Application |

Widely used in building structures and engineering construction, such as room beams, ship beams, industrial furnaces, etc. |

|

loading port |

Any port in China |

|

Packaging |

Standard export packing or as your request |

|

Payment Method |

Wire transfer, spot letter of credit, Western Union, payment documents, acceptance documents, PayPal. |

|

model

|

|

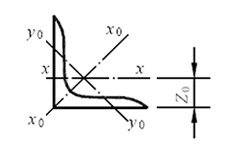

Single Angle Steel |

|

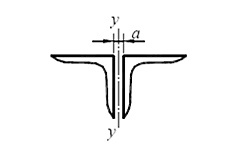

Double Angle Steel |

|||||||||||||

| Round Corners | Centroid Moment | Cross-sectional area | quality | Moment of inertia | Section modulus | Radius of gyration |

iy, 当 a 为下列数值 |

||||||||||

|

R |

Z0 |

A |

Ix |

Wxmax |

Wxmin |

ix |

ix0 |

iy0 |

6mm |

8mm |

10mm |

12mm |

14mm |

||||

|

(mm) |

(cm2) |

(kg/m) |

(cm4) |

(cm3) |

(cm) |

(cm) |

|||||||||||

|

L90×

|

6 |

10 |

24.4 |

10.64 |

8.35 |

82.77 |

33.99 |

12.61 |

2.79 |

3.51 |

1.8 |

3.91 |

3.98 |

4.05 |

4.12 |

4.2 |

|

|

7 |

24.8 |

12.3 |

9.66 |

94.83 |

38.28 |

14.54 |

2.78 |

3.5 |

1.78 |

3.93 |

4 |

4.07 |

4.14 |

4.22 |

|||

|

8 |

25.2 |

13.94 |

10.95 |

106.5 |

42.3 |

16.42 |

2.76 |

3.48 |

1.78 |

3.95 |

4.02 |

4.09 |

4.17 |

4.24 |

|||

|

10 |

25.9 |

17.17 |

13.48 |

128.6 |

49.57 |

20.07 |

2.74 |

3.45 |

1.76 |

3.98 |

4.06 |

4.13 |

4.21 |

4.28 |

|||

|

12 |

26.7 |

20.31 |

15.94 |

149.2 |

55.93 |

23.57 |

2.71 |

3.41 |

1.75 |

4.02 |

4.09 |

4.17 |

4.25 |

4.32 |

|||

|

L100× |

6 |

12 |

26.7 |

11.93 |

9.37 |

115 |

43.04 |

15.68 |

3.1 |

3.91 |

2 |

4.3 |

4.37 |

4.44 |

4.51 |

4.58 |

|

|

7 |

27.1 |

13.8 |

10.83 |

131 |

48.57 |

18.1 |

3.09 |

3.89 |

1.99 |

4.32 |

4.39 |

4.46 |

4.53 |

4.61 |

|||

|

8 |

27.6 |

15.64 |

12.28 |

148.2 |

53.78 |

20.47 |

3.08 |

3.88 |

1.98 |

4.34 |

4.41 |

4.48 |

4.55 |

4.63 |

|||

|

10 |

28.4 |

19.26 |

15.12 |

179.5 |

63.29 |

25.06 |

3.05 |

3.84 |

1.96 |

4.38 |

4.45 |

4.52 |

4.6 |

4.67 |

|||

|

12 |

29.1 |

22.8 |

17.9 |

208.9 |

71.72 |

29.47 |

3.03 |

3.81 |

1.95 |

4.41 |

4.49 |

4.56 |

4.64 |

4.71 |

|||

|

14 |

29.9 |

26.26 |

20.61 |

236.5 |

79.19 |

33.73 |

3 |

3.77 |

1.94 |

4.45 |

4.53 |

4.6 |

4.68 |

4.75 |

|||

|

16 |

30.6 |

29.63 |

23.26 |

262.5 |

85.81 |

37.82 |

2.98 |

3.74 |

1.93 |

4.49 |

4.56 |

4.64 |

4.72 |

4.8 |

|||

|

L110× |

7 |

12 |

29.6 |

15.2 |

11.93 |

177.2 |

59.78 |

22.05 |

3.41 |

4.3 |

2.2 |

4.72 |

4.79 |

4.86 |

4.94 |

5.01 |

|

|

8 |

30.1 |

17.24 |

13.53 |

199.5 |

66.36 |

24.95 |

3.4 |

4.28 |

2.19 |

4.74 |

4.81 |

4.88 |

4.96 |

5.03 |

|||

|

10 |

30.9 |

21.26 |

16.69 |

242.2 |

78.48 |

30.6 |

3.38 |

4.25 |

2.17 |

4.78 |

4.85 |

4.92 |

5 |

5.07 |

|||

|

12 |

31.6 |

25.2 |

19.78 |

282.6 |

89.34 |

36.05 |

3.35 |

4.22 |

2.15 |

4.82 |

4.89 |

4.96 |

5.04 |

5.11 |

|||

|

14 |

32.4 |

29.06 |

22.81 |

320.7 |

99.07 |

41.31 |

3.32 |

4.18 |

2.14 |

4.85 |

4.93 |

5 |

5.08 |

5.15 |

|||

|

L125× |

8 |

14 |

33.7 |

19.75 |

15.5 |

297 |

88.2 |

32.52 |

3.88 |

4.88 |

2.5 |

5.34 |

5.41 |

5.48 |

5.55 |

5.62 |

|

|

10 |

34.5 |

24.37 |

19.13 |

361.7 |

104.8 |

39.97 |

3.85 |

4.85 |

2.48 |

5.38 |

5.45 |

5.52 |

5.59 |

5.66 |

|||

|

12 |

35.3 |

28.91 |

22.7 |

423.2 |

119.9 |

47.17 |

3.83 |

4.82 |

2.46 |

5.41 |

5.48 |

5.56 |

5.63 |

5.7 |

|||

|

14 |

36.1 |

33.37 |

26.19 |

481.7 |

133.6 |

54.16 |

3.8 |

4.78 |

2.45 |

5.45 |

5.52 |

5.59 |

5.67 |

5.74 |

|||

|

L140×

|

10 |

14 |

38.2 |

27.37 |

21.49 |

514.7 |

134.6 |

50.58 |

4.34 |

5.46 |

2.78 |

5.98 |

6.05 |

6.12 |

6.2 |

6.27 |

|

|

12 |

39 |

32.51 |

25.52 |

603.7 |

154.6 |

59.8 |

4.31 |

5.43 |

2.77 |

6.02 |

6.09 |

6.16 |

6.23 |

6.31 |

|||

|

14 |

39.8 |

37.57 |

29.49 |

688.8 |

173 |

68.75 |

4.28 |

5.4 |

2.75 |

6.06 |

6.13 |

6.2 |

6.27 |

6.34 |

|||

|

16 |

40.6 |

42.54 |

33.39 |

770.2 |

189.9 |

77.46 |

4.26 |

5.36 |

2.74 |

6.09 |

6.16 |

6.23 |

6.31 |

6.38 |

|||

|

L160×

|

10 |

16 |

43.1 |

31.5 |

24.73 |

779.5 |

180.8 |

66.7 |

4.97 |

6.27 |

3.2 |

6.78 |

6.85 |

6.92 |

6.99 |

7.06 |

|

|

12 |

43.9 |

37.44 |

29.39 |

916.6 |

208.6 |

78.98 |

4.95 |

6.24 |

3.18 |

6.82 |

6.89 |

6.96 |

7.03 |

7.1 |

|||

|

14 |

44.7 |

43.3 |

33.99 |

1048 |

234.4 |

90.95 |

4.92 |

6.2 |

3.16 |

6.86 |

6.93 |

7 |

7.07 |

7.14 |

|||

|

16 |

45.5 |

49.07 |

38.52 |

1175 |

258.3 |

102.6 |

4.89 |

6.17 |

3.14 |

6.89 |

6.96 |

7.03 |

7.1 |

7.18 |

|||

|

|

12 |

16 |

48.9 |

42.24 |

33.16 |

1321 |

270 |

100.8 |

5.59 |

7.05 |

3.58 |

7.63 |

7.7 |

7.77 |

7.84 |

7.91 |

|

|

14 |

49.7 |

48.9 |

38.38 |

1514 |

304.6 |

116.3 |

5.57 |

7.02 |

3.57 |

7.67 |

7.74 |

7.81 |

7.88 |

7.95 |

|||

|

16 |

50.5 |

55.47 |

43.54 |

1701 |

336.9 |

131.4 |

5.54 |

6.98 |

3.55 |

7.7 |

7.77 |

7.84 |

7.91 |

7.98 |

|||

|

18 |

51.3 |

61.95 |

48.63 |

1881 |

367.1 |

146.1 |

5.51 |

6.94 |

3.53 |

7.73 |

7.8 |

7.87 |

7.95 |

8.02 |

|||

|

L200× |

14 |

18 |

54.6 |

54.64 |

42.89 |

2104 |

385.1 |

144.7 |

6.2 |

7.82 |

3.98 |

8.47 |

8.54 |

8.61 |

8.67 |

8.75 |

|

|

16 |

55.4 |

62.01 |

48.68 |

2366 |

427 |

163.7 |

6.18 |

7.79 |

3.96 |

8.5 |

8.57 |

8.64 |

8.71 |

8.78 |

|||

|

18 |

56.2 |

69.3 |

54.4 |

2621 |

466.5 |

182.2 |

6.15 |

7.75 |

3.94 |

8.53 |

8.6 |

8.67 |

8.75 |

8.82 |

|||

|

20 |

56.9 |

76.5 |

60.06 |

2867 |

503.6 |

200.4 |

6.12 |

7.72 |

3.93 |

8.57 |

8.64 |

8.71 |

8.78 |

8.85 |

|||

|

24 |

58.4 |

90.66 |

71.17 |

3338 |

571.5 |

235.8 |

6.07 |

7.64 |

3.9 |

8.63 |

8.71 |

8.78 |

8.85 |

8.92 |

|||

Packing and delivery

The company is equipped with a complete product production line. The main devices include cutting machines, bending machines, punching machines, cutting machines, polishing machines, shear machines, wire drawing machines, etc. Our traditional advantages are sufficient inventory, excellent quality, low -cost, short -term delivery time and considerate services.

CLIENT FEEDBACK

He company's products sell well all over the world, and have been exported to more than 70 countries in the Middle East, South Africa, Southeast Asia, Latin America and other regions Since its establishment, the company has developed rapidly.

CUSTOMER VISIT

Our company 'management has been engaged in steel industry for more than 20 years, full of experience for managing team and strong business relations with our valuable customers and factories.

Customer Visit

Customer Visit

Customer Visit

APPLICATION AREAS

Ship

Wind power

Oil mining

Airplane

Motorcycle

Car manufacturing

Mining

FACTORY WORKSHOP

FAQ

Q: Are you a manufacturer?

Q: How can we get the offer?

Q. Are your prices competitive?

Q: Can we visit your factory?

Q: How can we get the offer?

Q: Do you provide samples? is it free or extra?

RELATED PRODUCTS

GET A FREE QUOTE